Share

Pin

Tweet

Send

Share

Send

Materials:

- corner 30x30 mm - 60 cm;

- steel strip 70 mm wide - 15 cm;

- strong window hinges - 2 pcs.;

- bolts, nuts, thumbs.

Making a sheet bending machine

First you need to make the main workpiece. A piece of 15 cm should be cut from the strip. The corner is cut into 4 pieces of 15 cm each.

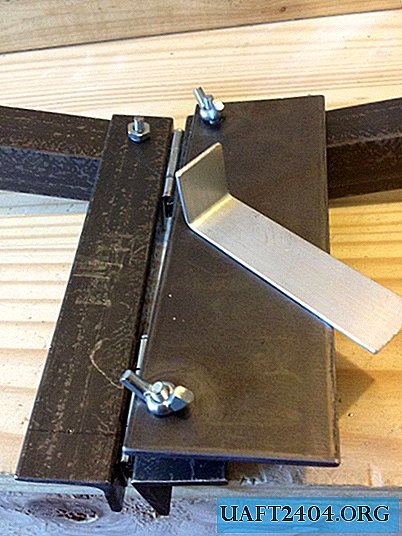

Handles of the machine are made from two corners. One hole is made in them. You need to drill in the center of one of the sides at a distance of 12 mm from the edge, as in the photo. Important! The hole in the second corner is made in mirror image relative to the first workpiece.

The remaining 2 corners are connected by a pair of strong window hinges. For this, a pair of through holes is made in each of them. You need to get the design, as in the photo.

On the corners connected by loops it is done through an opening for joining handles. You need to drill at a distance of 12 mm from the edges, as in the photo. At one corner, another hole is made from the second edge at the same distance.

On the segment of the strip, you need to make 2 holes at a distance of 12 mm from the edges. It is important that they completely coincide with those that are on one of the corners with loops. At the same time, they need to be shifted 3 mm closer to the long side.

Now you need to assemble all the parts together. The corners for pens are substituted from below under the workpiece with loops. The machine side with one hole is pulled together with a short bolt. In the half with two holes, long bolts with flaps are used. This allows you to grab and squeeze the strip.

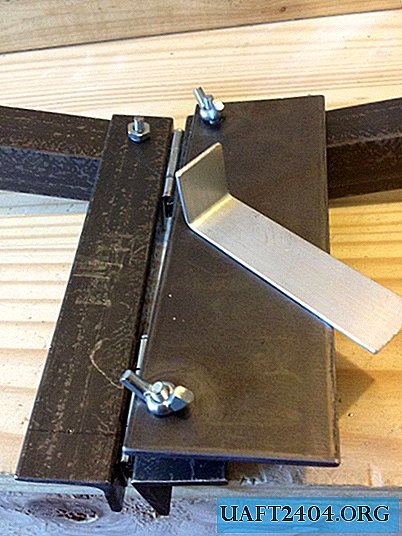

How to use

A plate of soft metal or sheet metal of the desired length can be inserted into a listogib under the strip. It is set exactly 90 ° relative to the machine parts. The workpiece is clamped by twisting the lamb. After that, pulling the handles you need to bend the listogib. In this case, the plate will bend into the mounting bracket. Further in it it remains to make a hole and use it for its intended purpose.

The machine is done very quickly, and with a minimum set of tools. The resulting corners can be used in the manufacture of home-made furniture, cages for animals, strengthening frame structures, etc.

Original article in English

Share

Pin

Tweet

Send

Share

Send