Share

Pin

Tweet

Send

Share

Send

Walk-through switches are usually used in long corridors or at large distances when you need to turn on or off in one place and turn on or off in another lighting or electrical appliances. In this case, you have to pull 3-wire or more cables.

Below is a diagram of a standard feed-through switch:

The proposed electronic switch is free from these shortcomings, it is installed in the junction box and buttons (switches) are connected from it in parallel with the signal wires, which can independently turn the lighting or other devices on and off.

The buttons from the bell or any other buttons without locking are used as switches (they pressed release, turned on the light, pressed once again released and turned off the light), there are also non-locking switches on sale.

Will need

For manufacturing it is necessary:

- Klemnik in a payment with a step of 5 mm. 3 pcs. (you can not put, but just solder the wires)

- Resistor 1K 1206 - 2 pcs.

- 100K resistor 1206 - 6 pcs.

- Resistor 470 K 1206 - 1 pc.

- Resistor 10K 1206 - 1 pc.

- Capacitor 0.01 uF 1206 - 1 pc.

- Capacitor 0.1 uF 1206 - 2 pcs.

- 10 uF capacitor 1206 - 1 pc.

- Diode 4007 (any 600-800 V suitable size) 1 pc.

- 12 V Zener Diode BZV55-C12 (2 pcs at 5.6 V possible) 1 pc

- DF10S diode bridge (any suitable size for 1 A 600-1000 V) 1 pc.

- IRF840 Transistor - 1 pc.

- ICM7555 microcircuit (analogue of ALD555, LMC555, TS555, TLC555) - 1 pc.

All SMD components because the circuit board is made for them.

Scheme

Here is the actual device diagram:

Description

a trigger is created on the microcircuit, R1, R2 can be set to 470 Ohm-1.5 K, they are needed to improve noise immunity and partly safety (the design has galvanic connection to the network).

The circuit R6, C3 is needed so that the trigger is always off when the power is turned on.

Capacitor C4 is a power filter, a Zener diode V2 limits the power supply to 12V / there is a place on the board for installing 2 zener diodes of 5.6V in series, and when using one at 12 V, you must put a jumper in the place of the second one, it is indicated on the board by V2 *.

Resistor R7 can be installed with a nominal value of 470 Ohm -20 K, it is needed to stably open the transistor and suppress its self-excitation at the time of opening / closing.

R8-R10 suppress the mains voltage (why are there 3 in series? Because 1 resistor in the 1206 housing is designed for a voltage of not more than 200V and 3 are installed for safety and reliability)

A voltage of approximately 12 V comes to the buttons or switches without fixing, and you can use any of the most low-voltage ones, but the circuit is connected to the network, be careful when checking!

Board Assembly:

We cut out a board with a size of 20x60 mm from a single-sided foil fiberglass, clean it with a fine sandpaper, degrease it. We print a board on a laser printer without saving ink on glossy magazine paper.

Files of the PCB can be downloaded here:

fajly.zip 113.48 Kb (downloads: 158)

Using the LUT method, we apply a pattern and etch in ferric chloride. Wash off the toner with acetone and clean with a fine skin. We serve the tracks and wash off the remnants of the flux. Solder all the components from the side of the tracks.

Wash off the flux! it is very important! The microcircuit is quite high resistance and if the active flux may not work!

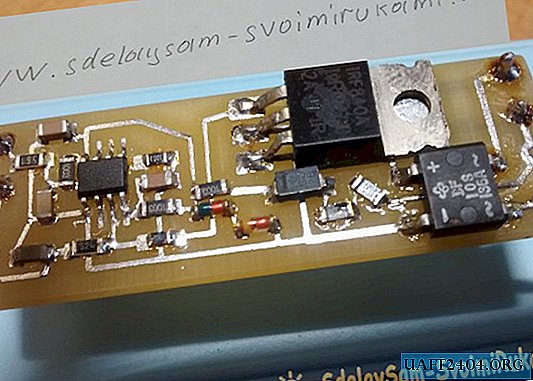

It should look something like this:

Be careful - the design is connected to a 220 V network! Observe precautions!

We check the installation!

We connect a light bulb, a button, a power cord. We include 220 V in the network. Be careful - the design is connected to the 220 V network! Observe precautions!

We check the performance. If everything works fine, we take a heat-shrink tube of a suitable diameter and pack the board there for safety.

Characteristics:

The maximum load is -150 W (limited by the diode bridge and the transistor when replaced with more powerful loads, you can increase it).

Supply voltage -180-250 V.

Power consumption off -0.1 watts.

The video below shows the operation of the device.

You can not do a board at all if you take a breadboard and solder on it the usual DIP elements with pins by connecting them with wire.

Only it will be a little more. Any questions - write I will answer.

Share

Pin

Tweet

Send

Share

Send