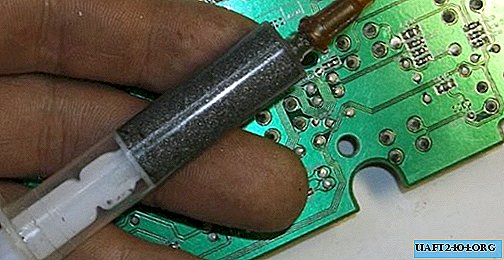

In the manufacture of volutes and curls by cold forging, a reinforced square section profile with a wall thickness of 1.5 mm is often used.

In order to strengthen a professional pipe at home, a compact and practical home-made machine or, as the author himself calls it, a profile pipe reinforcement unit is useful.

And the first thing the author bought in the car shop was two gears for the timing belt crankshaft with an inner diameter of 22 mm. Based on the size of the gears, you need to grind two shafts on a lathe (or order lathes).

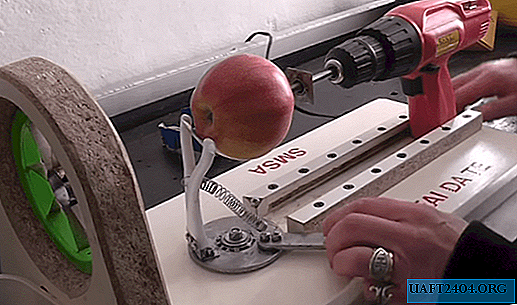

The main stages of work

For the manufacture of a makeshift machine, four bearings and clips for them, cut from a metal pipe of suitable diameter, will also be required. Still, four segments of the M12 stud with nuts are required.

It will also be necessary to cut two plates 118 mm wide and 142 mm long from a piece of metal 7-8 mm thick. They need to drill holes with a step drill with a diameter of 13 and 20 mm.

Then, bearings should be welded to the plates, and two bearings and a gear should be mounted on the shafts. After that, you can begin to assemble this device.

For details on how to assemble a home-made machine for reinforcing a profile pipe, we recommend that you look in the video on the site.