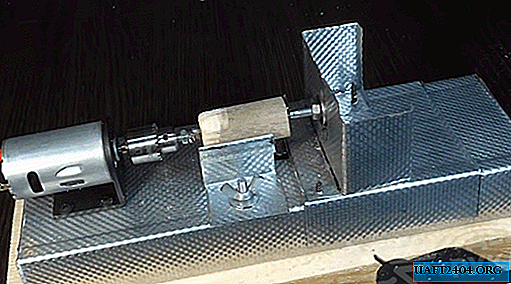

In Chinese online stores, you can often find primitive lathe models that are expensive. But you can make the same simple functional lathe with your own hands from a metal profile 100 mm wide.

The first step is to make the bed of the lathe. To do this, cut a length of 300 mm from the profile. Since the profile is thin, you can do without a grinder - cut off with scissors for metal.

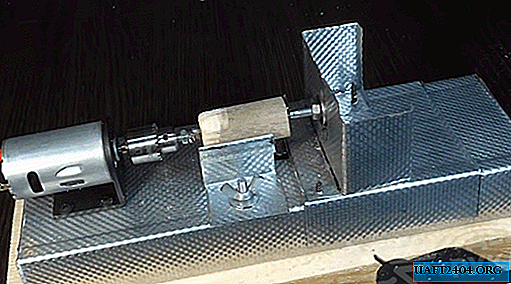

In the next step, you will need to install a 12V motor on the bed. To do this, we first attach the bracket that comes with the motor, and then we install the engine.

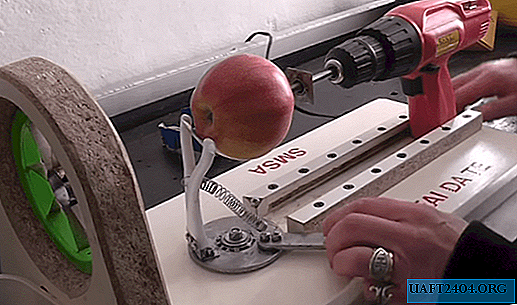

Step-by-step lathe manufacturing process

We put a small cam cartridge on the shaft of the electric motor (this can be purchased at Aliexpress). After that, it will be necessary to make a tailstock to press the workpiece to the cartridge. To do this, you can use a piece of metal profile 10 cm long, having previously cut the stiffness angle.

You will also need a piece of profile 7 cm long, which you need to mark and bend. This will also be part of the lathe tailstock. We install a bearing in the same design.

At the next stage of work, it will be necessary to make a support from an ordinary steel washer for holding the bearing in its landing "nest". We fasten it to the metal profile using small screws.

Then it remains only to make a latch for the tailstock and a supporting table for incisors. In the video on the site you can see in more detail how to make a simple wood lathe from a metal profile.