Using a universal tool for bending square and reinforcing bars, which is easy to make independently from materials at hand, you can not only bend the workpiece at the right angle, but also create cold forging elements.

One of the obvious advantages of this homemade product is its practicality and safety. When processing metal billets "cold" it is not necessary to heat them, as in hot forging.

Therefore, in the process, you will not need a blacksmith hearth, holding the workpieces at high temperature, and also do not need skills in working with hot metal.

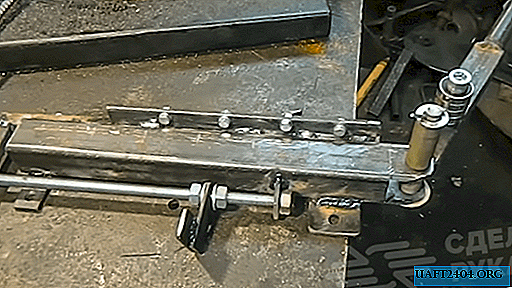

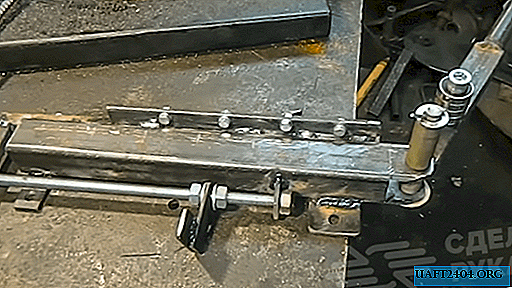

The first step is to cut a piece of 35 cm long from a 40x40 mm profile pipe. Then you will need to make a two-piece handle from a section of a 30x20 mm profile and a round pipe with a diameter of ½ inch. In this case, the round tube acts as a bending lever.

Work process

In the 30x20 profile section, two through holes with a diameter of 12 mm must be drilled, and, on the other hand, the M12 nuts must be welded.

To weld the nuts evenly, we screw them onto the M12 bolts, which we first insert into the drilled holes. At the end of the profile, we make a selection so that the jet thrust sleeve can be welded.

In the section of the profile pipe 40x40 mm 35 cm long, it is necessary to cut out the "ears" for fastening the jet thrust sleeve. To connect the two structural elements, a piece of the rod from the shock absorber of a car or motorcycle is suitable.

For a detailed process of making a home-made universal tool for bending squares and reinforcement and creating elements of cold forging, see the video on the website. Did you like this homemade product? Write in the comments.