The very idea of making a homemade grinder from a hand mill is quite unusual, but at the same time very interesting. This homemade product will appeal to those home masters and "kulibin" who prefer to do different useful things from what is currently at hand.

First of all, we cut out a suitable-sized disk from a steel sheet 3-4 mm thick, in the center of which a hole must be drilled. If there is no milling cutter or crown for the metal of the desired diameter, you can first drill small holes in a circle using a conventional drill, and then knock out the "core" with a hammer.

The main stages of work

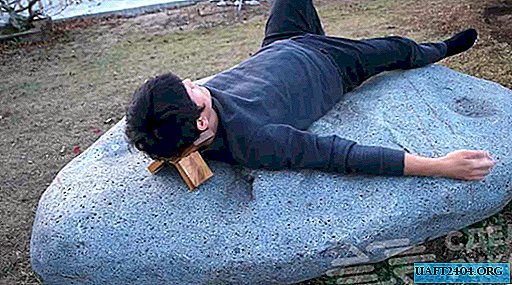

Irregularities at the edges of the hole are treated with a drill or dremel (as an option, you can do with a simple file, but this will take more time). Then in a wooden blank we drill a hole with a diameter of 10 mm in the center, fill it with epoxy, and then insert a steel “finger” inside.

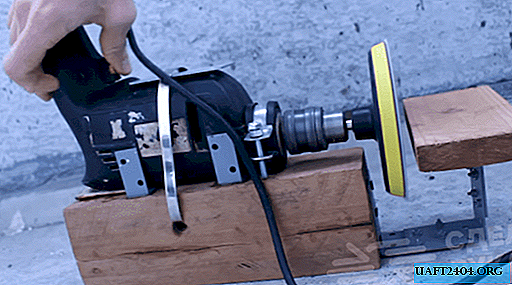

Next, we process a wooden blank on a grinding machine, so that in the end we get a roller with a diameter of 23 mm. We weld plates with pieces of a corner to a steel disk with a hole drilled in the center - this will be a platform for an emery tape. We attach the resulting part to the sole of the manual router.

From a piece of a profile pipe 20x30 mm and a wheel, we make a tension roller, which must be fixed to the site, and also set the driven wheel. Then we put on a piece of sanding tape cut to size, we fix the milling cutter to the table and the home-made grinder is completely ready for work.