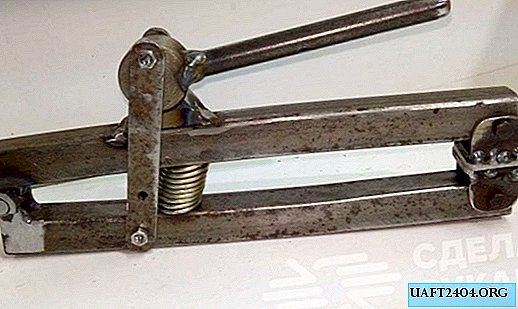

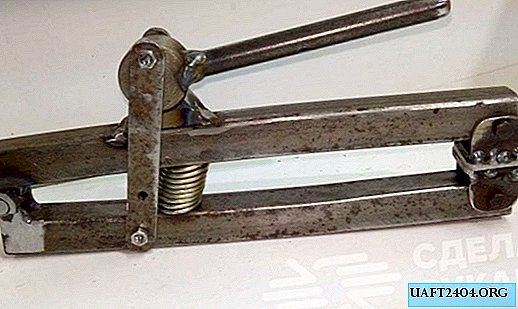

One of the varieties of quick-clamping clamps are eccentric clamps. Moreover, you can make such devices with your own hands, because they are very simple to manufacture. Please note that the use of homemade clamps with an eccentric fixation reduces the time in the process of processing a large number of workpieces.

To turn the eccentric, a handle is used, and the clamp itself is made of profile pipes. The main advantages of homemade clamps with an eccentric can be distinguished by the simplicity and compactness of the design, as well as speed - it takes less time to fix the workpiece than, for example, when using threaded clamps.

Eccentric Clamp Making Process

First of all, it is necessary to give the profile pipe a slightly curved shape on the rolling rollers, after which we cut it in half with a grinder and connect it together using a hinge. Next, we make the eccentric clamp itself and attach it to the clamp. We install a spring between the profile pipes. We also weld the handle to the eccentric.

At the ends of the profile pipes, we fix the jaws with bolts and nuts. Moreover, they must remain mobile. Now the homemade steel clamp with an eccentric lock is ready for use. If desired, the surface can be sanded and painted for a more aesthetic appearance. As for the use of such a clamp, then everything is simple.

The clamp with an eccentric is attached to the work table or workbench with the lower plane using F- or G-shaped screw clamps (bolting can be made if necessary). Then a metal or wooden workpiece is clamped between the jaws, and you can begin to process it. In fact, this is not even a clamp, but a home-made desktop vice with a vertical clamp. But in any case, the design is very convenient.