Using an angle grinder, you can perform a variety of metal processing operations. However, using additional devices that are easy to make with your own hands from improvised materials, you can significantly expand the functionality of the grinder.

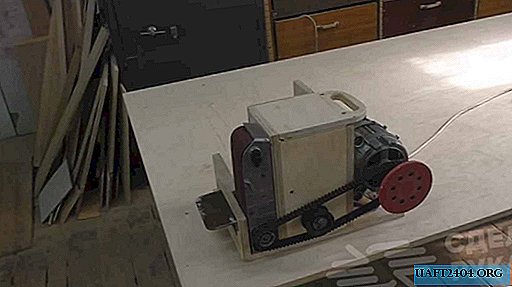

Making a carriage for angle grinder

To make this device, you will need to find in the workshop a small piece of a pipe of rectangular cross section with dimensions of sides 4x6 cm, while the length of the segment should be 150 mm.

Further, using a grinder or a manual jigsaw with a hacksaw for metal, it is necessary to cut a corner with sides of 5x3.5 cm from this piece of the profile pipe.

Two plates of different widths will also need to be cut from the remaining part of the profile pipe: the first strip is 2 cm wide, the second is 2.5 cm. They will also need to be filed to remove all burrs on the side surfaces.

Construction assembly process

After all the blanks necessary for the manufacture of the device are cut, you can proceed to electric welding work. To do this, you will need to use a profile pipe with side dimensions of 25x25 mm of any length convenient for you (but not less than 1 m), which first will need to be wrapped with a sheet of thick thin paper (to obtain a small gap).

Next, we expose the blanks along the pipe and weld the structural elements together. So that the parts do not "scatter" in different directions during welding, it is better to fix them with clamps. After welding and grouting the grinder, the fixture is ready for use.

It remains only to attach to the angle grinder, using two steel strips with holes for bolting. Using such a movable carriage and a guide pipe, grinders can perform perfectly even cuts of sheet metal or other building materials.