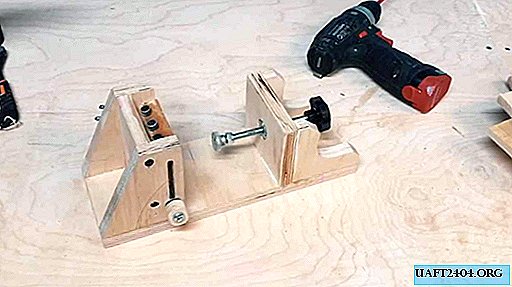

In metal forging, torsion bars are often used - stripes or square rods twisted in the longitudinal direction.

For the manufacture of these same torsion bars, you can use a simple fixture from a profile pipe, bearings and metal scraps.

First you need to cut two pieces of a square bar, and with the help of a grinder cut small grooves in them along the width of two bearings.

The main stages of work

Next, it will be necessary to drill one hole in the segments of the square, and thread into them. Then the workpieces must be welded to the inner race of the bearings.

At the next stage, it is necessary to cut four pieces of the corner, and then weld two workpieces from them. They will be worn on a profile pipe 30 * 30 mm.

The author welds two pieces of a strip of metal to one of these blanks. The second workpiece from the corners must be welded to the outer race of the bearings. Welds must be cleaned with a grinder.

Then you need to weld two handles to square rods (they can be made of smooth reinforcement). A profile pipe is clamped in a vice, and previously prepared parts are put on it. The device is ready, you can get to work.

For details on how to make a simple tool for making torsion bars "on the cold" with your own hands, see this video.