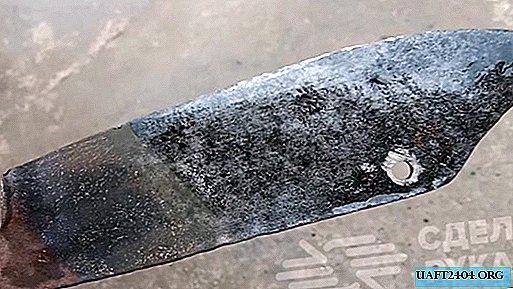

Very often it is required to clean the tool from rust at home, but it is not always possible to do it quickly, without unnecessary efforts, and most importantly, for the result to live up to expectations.

One of the available and effective ways to remove corrosion deposits from the metal surface is the electrolytic method using a constant current source. In this case, the electrolysis process itself occurs in an aqueous solution of soda ash.

Milestones for rust removal

The first step for this experiment will require a direct current source - you can use a conventional power supply with a PC (at least 250 W). The positive contact connects to stainless steel, and the negative contact connects to the tool or part that shows signs of corrosion.

If there is a lot of rust on the surface of the product or, for example, the electrolysis process is very slow, then an inverter-type welding machine can be used as a power source for this experiment instead of a computer PSU. In this case, set the minimum current (20, 40 or 60 Amps).

We lower the workpiece and the stainless plate into a container with a saturated aqueous solution of soda ash. Then we connect the terminals of the welding machine and start the electrolysis process. To speed up the reaction, a current of 100-140 A can be set on the welding machine.

How to remove rust from a metal surface using an inverter welding machine, see the video on our website.