If you remove the bearing from the shaft using a conventional hammer, screwdrivers and other improper means that are not very suitable for this, then there is a high probability of damage to the shaft or the bearing itself. Such homemade "barbaric" methods are not the best, and also ineffective.

To quickly remove the bearing, special devices are used - pullers. They come in different sizes, configurations and types (for example, manual mechanical or pneumatic). In this review, we will consider the manufacturing option of a homemade impact puller.

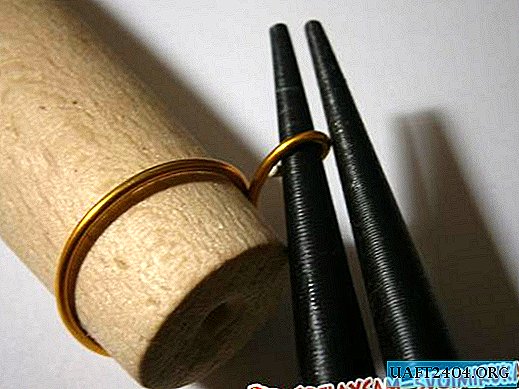

To do this, you will need a manual clamp with a clamp (also known as a "dog" in the people), as well as a piece of steel round bar, a bolt and the percussion element itself, which will move along the bar: an elongated blank or metal round welded in sausage. "

The main stages of work

First of all, if there are rubber pads on the handles on a manual clamp with a latch, they must be removed. If there are no overlays, then we unscrew the bolt from the handle, and then proceed to the machining.

We clamp the tool in a vice and, using a grinder with a cutting disc, cut out grippers for bearings in two jaws.

Next, cut a piece 30-35 cm long from the steel round timber and weld to it a bolt that was unscrewed from the clamp handle. Then we put on the axis the shock part in the form of a metal blank, and at the end of the bar we weld a large washer.

See the video on the website for the detailed process of manufacturing a bearing shock puller from a manual clamp with a retainer.